Dealing with Lignite

In this article, F. Ball technical representative Gary Kenworthy, provides a solution for dealing with the relatively common problem of lignite.

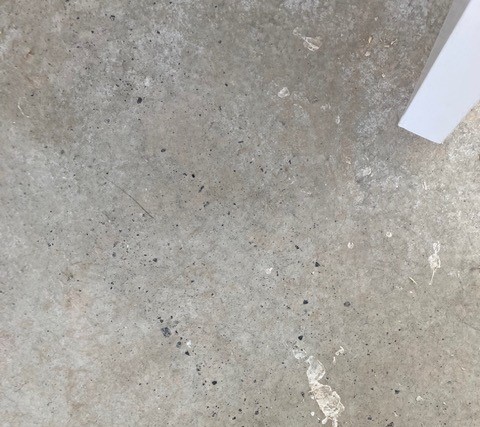

While undertaking a site visit to advise on subfloor preparation prior to the installation of Luxury Vinyl Tiles (LVTs) in the lounge, open-plan kitchen-dining room, hallway and toilet areas on the ground floor of two domestic properties, with a total area of 120m2, it was noted that the concrete screed subfloor was contaminated with lignite. There were also several cracks in the screeds.

Uncommon Issue of Lignite

In one property, laitance was visible along with paint and plaster residues. The contaminated subfloor base also contained lignite, a soft, low grade of coal, which is naturally present in some aggregate sources. Although it was once unusually to find it, it is becoming increasingly common. When it is present, it needs to be dealt with, either by removal or encapsulation. In the other residence, a small section of plastic debris was seen about 3mm below the surface, which should be extracted.

When conducting any flooring installation, it’s important to ensure the subfloor is free of contaminants that may interfere with the adhesion of subsequently applied subfloor preparation products and floorcoverings. A particular problem with lignite is that it is sensitive to moisture – particles that absorb water can expand and protrude from the subfloor.

A routine moisture test also indicated that subfloor Relative Humidity (RH) levels in the utility rooms of both of the properties were below the limit for installing resilient floorcoverings without a moisture management solution in place, with one giving a reading of 61% and the other 62%. BS 8203, Code of practice for installation of resilient floor coverings, stipulates that subfloor moisture levels must be lower than 75% RH in these situations. However, even though the subfloor RH level was sufficiently dry, it was recommended that a waterproof surface membrane be applied to isolate the lignite from the moisture in any subsequently applied floor smoothing compounds.

Initial Steps

Prior to the application of a waterproof surface membrane, the contractor would need to mechanically remove paint, laitance, the majority of lignite and other contaminants from the screeds before vacuuming to leave a clean, dust-free, micro-textured surface.

Cracks in the concrete would need to be raked out and vacuumed to remove any dust and debris before being repaired. This could be achieved with Stopgap F77 waterproof surface membrane filled with sand or using suitable repair compound, such as F. Ball’s Stopgap 400, providing that they were static.

A single coat of Stopgap F77 waterproof surface membrane could then be applied to create a barrier between the lignite, where present, and moisture in subsequently applied subfloor preparation products. It should be applied using a 1.5mm x 5mm v-notched trowel, before rolling with a pre-coated roller to achieve a continuous pinhole-free finish.

Once the waterproof surface membrane had cured, it was recommended that the surface was primed using F. Ball’s Styccobond P141 primer. It is specially designed to promote the application characteristics of smoothing compounds when applied to non-absorbent surfaces, including waterproof surface membranes. When the primer was dry, contractors could apply a minimum 3mm thickness of Stopgap 1200 smoothing compound and allow it to dry to create a perfectly smooth base for floorcoverings.

Adhesive Recommendation

Finally, we advised that LVTs were installed according to the manufacturer’s instructions using F. Ball’s Styccobond F49 Hybrid PS temperature tolerant pressure sensitive adhesive, providing this is listed as compatible in our Recommended Adhesives Guide (RAG®).

The use of a high temperature grade adhesive was specified because of the potential for large patio doors in the kitchens to cause solar gain. High temperatures or extreme temperature fluctuations as a result of solar gain can cause floorcoverings to expand and contract significantly, which may lead to unsightly tenting in floorcoverings and gapping at the edges of LVTs over time.

Styccobond F49 is a solvent-free, water-based adhesive that develops the ultra-high bond strength to hold floorcoverings firmly in place when exposed to temperature fluctuations from -20°C up to +60°C. Its pressure sensitive characteristics would also help with the positioning and alignment of LVTs.

The good news was that this sticky situation was resolved and works could commence again within 48 hours, and the project has now been completed.

Gary Kenworthy is F. Ball technical representative for the North West.

F. Ball’s regional technical representatives provide advice to flooring contractors on how to get the most out of F. Ball products, including conducting site visits and producing case-specific reports advising on the best course of action for particular flooring projects. Find out who your technical representative is here.