What is it?

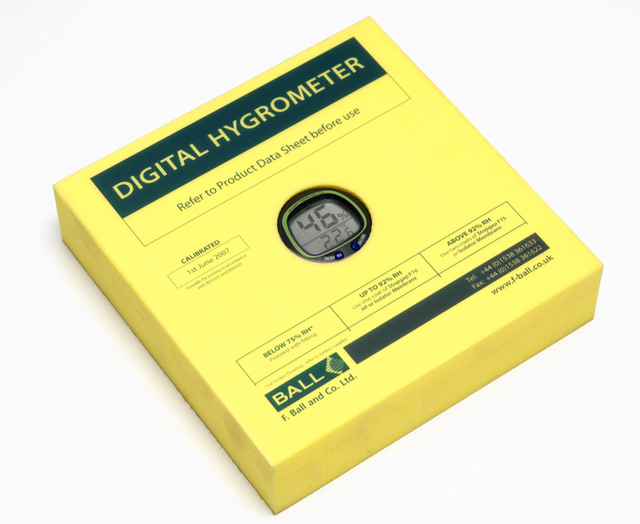

A calibrated digital hygrometer is a non-invasive device used to measure the moisture levels in a subfloor. It is the moisture measurement tool recommended by British Standards 5325, 8203 and 8201.

What is it used for?

It is used prior to the installation of floorcoverings to assess whether a subfloor is sufficiently dry to proceed with an installation. The digital hygrometer incorporates a thermo hygrometer that indicates both relative humidity and air temperature to provide an accurate measure of the moisture levels present in a subfloor. Relative humidity readings are expressed as a percentage.

How does it work?

- Remove the hygrometer in its insulating box from the packaging

- Apply the butyl tape provided around all four edges of the hygrometer insulating box to make an airtight seal around the base of the box

- Position the insulating box on the subfloor, ensuring the hygrometer remains switched off until it is conditioned for use. This process should be repeated at various points across the floor as necessary

- Once enough time has passed to allow the entrapped air to reach moisture equilibrium* with the subfloor, the hygrometer can be switched on and a reading taken

*Equilibrium can be assumed either when two consecutive readings taken at four hourly intervals show no change, or if the instrument is left in position overnight. This can take at least four hours on a 50mm thick screed where the damp proof membrane is placed between the base and the screed, and considerably longer for thicker floor constructions.

What’s next?

The readings from the hygrometer should inform the next steps taken. If the readings indicate RH levels of less than 75% (or 65% for wood flooring installations) no further steps need be taken, as the subfloor is sufficiently dry for the installation to continue as planned.

However, if the readings are above 75% or 65% respectively, a waterproof surface membrane must be installed before proceeding with the installation. Excess subfloor moisture is one of the most common causes of floor failure, but it can be avoided by installing a waterproof surface membrane to impede the passage of rising damp or residual construction moisture.

There are a number of options available should protection against excess moisture be required. Waterproof surface membranes, such as Stopgap F77 and Stopgap F78, or F. Ball’s loose-lay isolator membrane provide a barrier between excess moisture in subfloors and floorcoverings to impede the passage of damp.

To find out more about product testing or waterproof surface membranes, visit the F. Ball website.